Premium Hoists are available in the following product groups:

Premium Hoists

Technology that moves.

Devices that work precisely and reliably under the highest loads have borne the HADEF name for over 100 years.

The Premium line consistently continues the tradition of the highest product quality and safety.

Robust constructions and well-engineered assemblies “Made in Germany” guarantee the longest possible service life, even under extreme operating conditions.

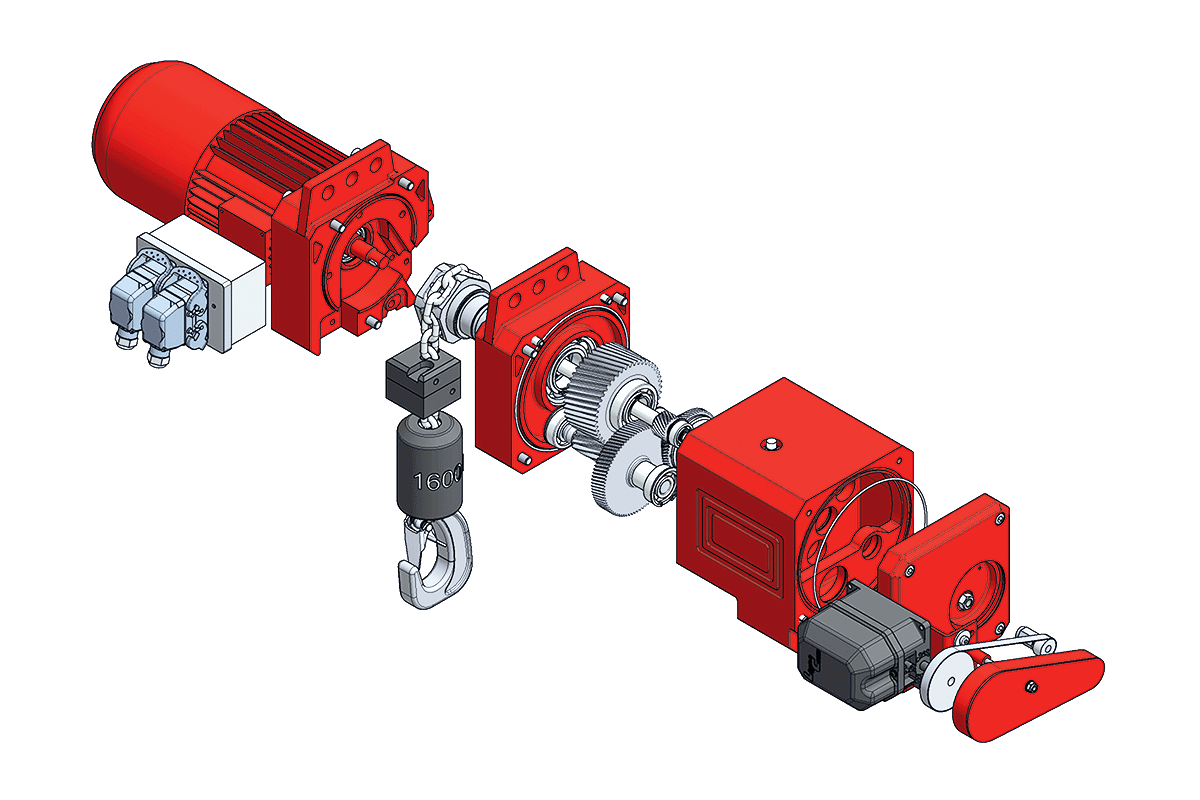

The modular building block system

With the AK series, HADEF has created a modular “building block system” for hoists.

The basic model of this chain hoist is used here in many variants: as a trolley, reel or electric trolley, with different load capacities.

The variants of the AK series

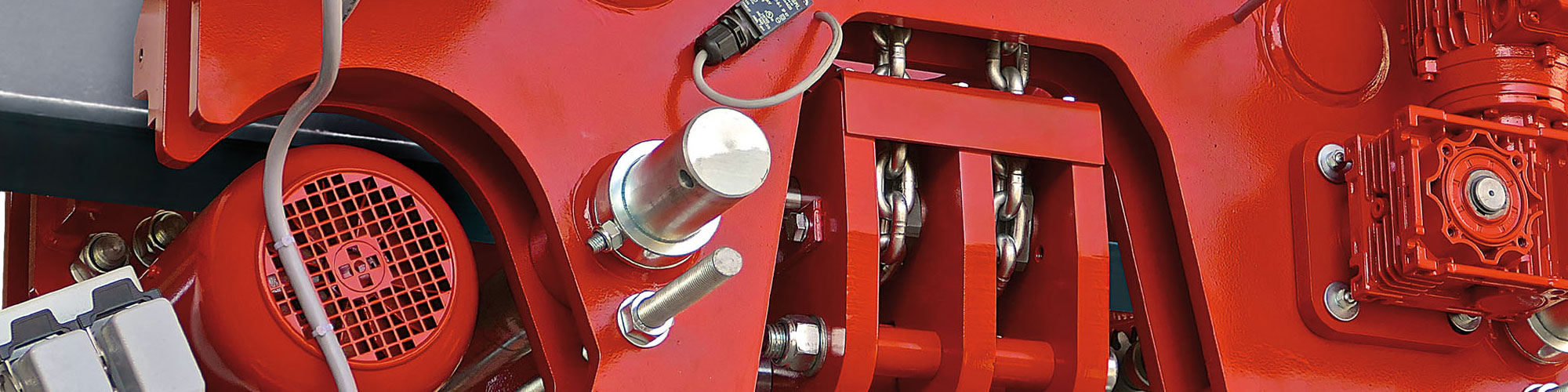

Quality to the smallest detail

Top technology consistently thought through and produced for maximum reliability and durability

All components of the HADEF Premium line are designed for durability and high loads. Thanks to the use of high-quality materials and modern manufacturing processes, the devices in the Premium Line are particularly hard-wearing and fail-safe.

milled, 5-pocket chain sprocket wheel made of hardened steel and long-lifetime chain resistant to wear

smooth running and increased product lifetime by precision gear with finely grinded helical geared pinions and toothed wheels

robust housing made of cast iron in GGG 40 quality

ong life seals (O-rings)

Safe chain infeed with anti-twist protection.

positionning switch for exact setting of load positions

robust brake motor with ventilation up to 100 % ED (duty cycle)

chain guide of hardened steel minimizes wear

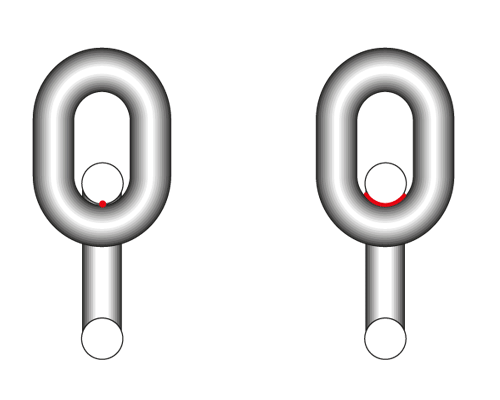

standard chain – punctual load

calibrated HADEF special chain – in line load

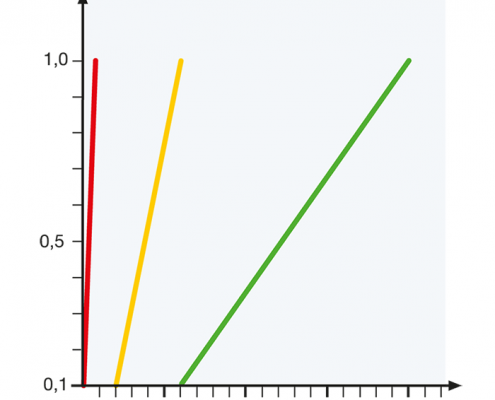

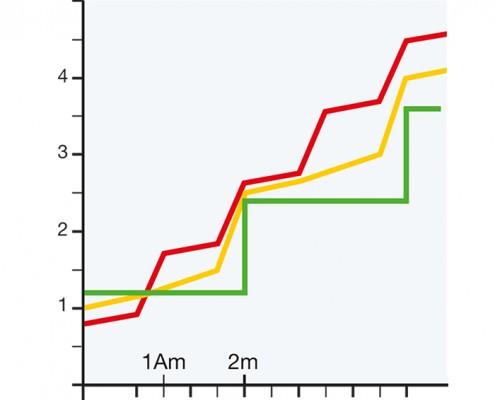

Advantage through research

Greater economy through innovative research into wear reduction.

The forces acting on the materials are measured in complex test procedures. The results of these tests are the basic data for our designers, whose task it is to continue to minimize wear and tear on the individual assemblies through optimal force distribution, with the aim of improving each new product generation a little bit.